-

1. Introduction to Six Sigma

-

2. Core Principles of Six Sigma and Lean

-

3. Six Sigma Methodologies

-

4. Six Sigma Tools and Techniques

-

5. The Belt System and Roles in Six Sigma

-

6. Metrics and Measurement

-

7. Implementing Six Sigma Across Industries

-

8. Benefits and Challenges of Six Sigma

-

9. Certification and Professional Development

-

10. Real-World Case Studies

-

11. Advanced Topics and Future Trends

-

12. Glossary and Key Terminology

6.1 Six Sigma Metrics

Six Sigma metrics are essential tools that measure and quantify process performance, helping organizations track their progress toward achieving quality and efficiency improvements. These metrics provide insight into the effectiveness of the Six Sigma methodology, guiding decision-making and helping to sustain continuous improvement.

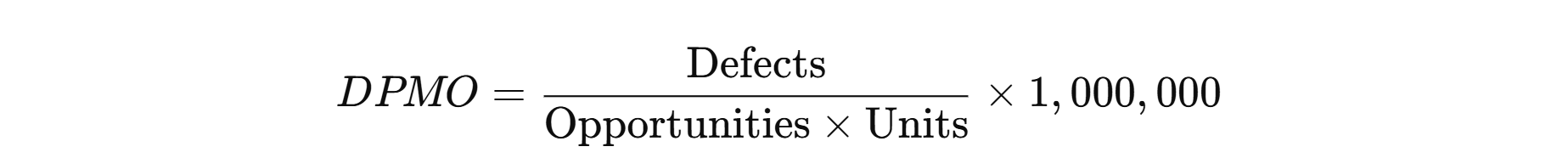

1. Defects per Million Opportunities (DPMO)

- Definition: Measures the number of defects in a process relative to the total number of opportunities for defects to occur.

- Formula:

- Purpose: Indicates the defect rate of a process, helping identify areas for improvement. A lower DPMO value reflects higher process quality.

- Importance: Essential for comparing the performance of different processes and tracking improvements over time.

2. Sigma Level

- Definition: Represents the process’s capability to produce defect-free products, measured in terms of standard deviations (sigma).

- Purpose: A higher sigma level indicates fewer defects. Six Sigma (a sigma level of 6) is considered an optimal target for near-perfect processes, with no more than 3.4 defects per million opportunities.

- Importance: Helps quantify the performance of a process and provides a benchmark for process improvement efforts.

- Levels:

- 1 Sigma: 690,000 defects per million opportunities.

- 2 Sigma: 308,000 defects per million opportunities.

- 3 Sigma: 66,800 defects per million opportunities.

- 4 Sigma: 6,210 defects per million opportunities.

- 5 Sigma: 233 defects per million opportunities.

- 6 Sigma: 3.4 defects per million opportunities.

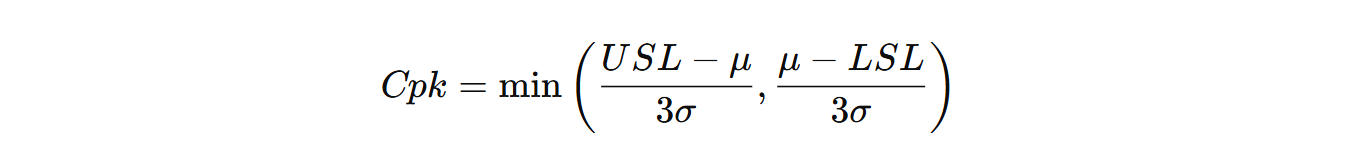

3. Process Capability Index (Cpk)

- Definition: Measures the ability of a process to produce output within specified limits.

- Formula:

- Where:

- USL: Upper Specification Limit

- LSL: Lower Specification Limit

- µ: Mean of the process

- σ: Standard deviation

- Purpose: Determines how well a process is performing relative to the specification limits. A higher Cpk value (greater than 1.33) indicates a capable process.

- Importance: A critical metric for determining whether a process can consistently meet quality standards.

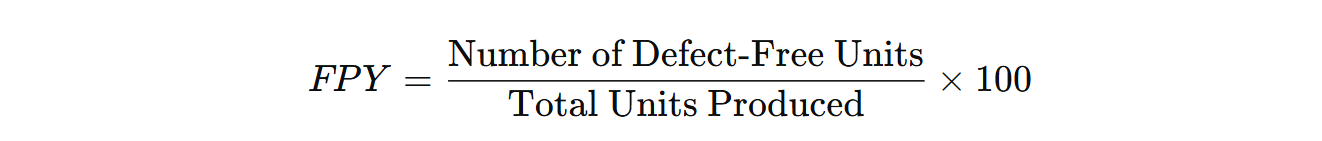

4. First Pass Yield (FPY)

- Definition: The percentage of products that meet quality standards on the first attempt, without needing rework or correction.

- Formula:

- Purpose: Measures the efficiency of a process in producing defect-free products on the first pass.

- Importance: A high FPY reflects a more efficient process, reducing the need for costly rework and improving overall productivity.

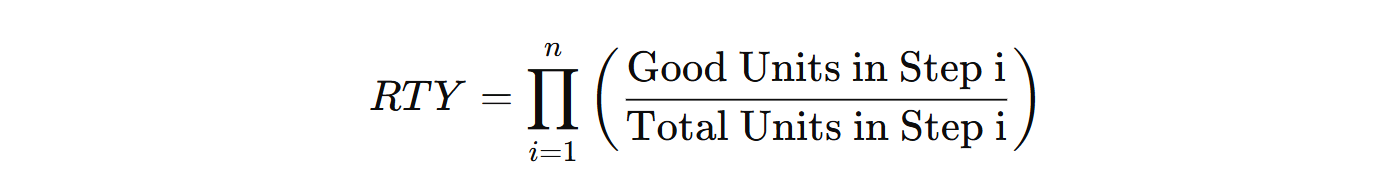

5. Rolled Throughput Yield (RTY)

- Definition: The overall probability of producing a defect-free unit through a multi-step process.

- Formula:

- Purpose: Evaluates the cumulative effect of defects across all steps in a process, providing a more comprehensive view of process performance.

- Importance: A key metric for understanding how defects accumulate at each stage of production.

6. Cost of Poor Quality (COPQ)

- Definition: The total cost incurred due to inefficiencies and defects in a process, including internal failures, external failures, and appraisal costs.

- Purpose: Helps quantify the financial impact of poor quality and demonstrates the value of implementing Six Sigma to reduce defects and improve processes.

- Importance: Tracking COPQ can provide a clear justification for investing in Six Sigma and process improvement initiatives.

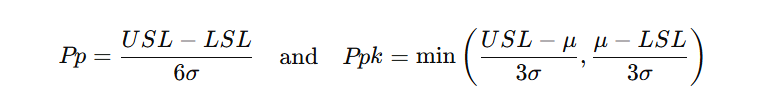

7. Process Performance Index (Pp and Ppk)

- Definition: Measures the capability of a process based on its actual performance.

- Pp: Measures process performance without considering the target value.

- Ppk: Takes into account both the process variation and how close the process mean is to the target value.

- Formula:

- Purpose: Indicates how well a process is performing and whether it can meet specifications consistently.

- Importance: Provides insights into whether a process is capable of producing products within specification limits.

8. Critical-to-Quality (CTQ) Attributes

- Definition: Specific measurable characteristics of a product or process that are essential to customer satisfaction and quality.

- Purpose: Identifies key factors that directly impact product or service quality.

- Importance: Helps focus Six Sigma efforts on areas that most influence customer satisfaction, ensuring that improvements align with business objectives.

Benefits of Six Sigma Metrics

- Data-Driven Decisions: Metrics provide objective data to guide process improvements and decision-making.

- Continuous Improvement: Tracking key metrics allows organizations to monitor progress and make adjustments to sustain improvement.

- Benchmarking: Comparing metrics against industry standards helps identify performance gaps and opportunities for further improvement.

- Cost Reduction: By focusing on reducing defects and inefficiencies, Six Sigma metrics help drive cost savings and higher profitability.

Six Sigma metrics are fundamental in measuring the effectiveness of process improvements, ensuring that organizations can achieve higher levels of quality, reduce defects, and ultimately deliver better products and services to customers.

Commenting is not enabled on this course.