In Lean Six Sigma, the 3Ms—Muda, Mura, and Muri—represent three critical forms of inefficiencies that hinder productivity and quality. Understanding and eliminating these elements is essential for achieving streamlined processes, improving customer satisfaction, and reducing costs. Let’s explore these concepts in detail.

1. Muda: Waste

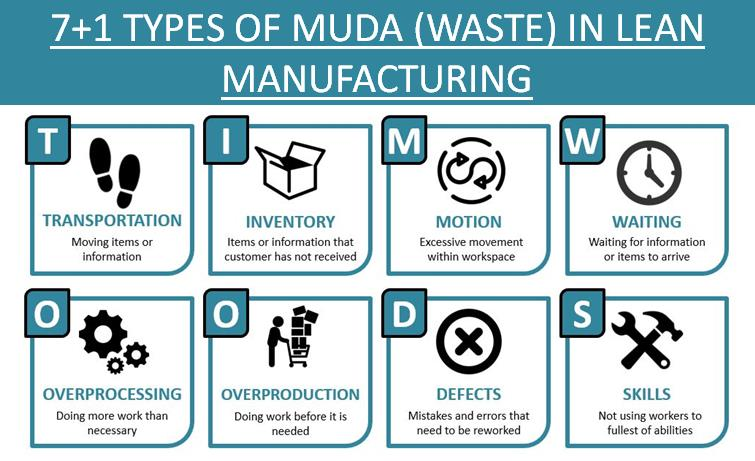

Muda refers to any activity or process that consumes resources without adding value to the customer. Lean Six Sigma identifies seven types of waste (TIMWOOD):

- Transportation

- Inventory

- Motion

- Waiting

- Overproduction

- Overprocessing

- Defects

-

How to Eliminate Muda:

- Map the value stream to identify non-value-added activities.

- Implement continuous flow to minimize waiting times.

- Optimize inventory levels to avoid overproduction and excess stock.

2. Mura: Unevenness

Mura refers to inconsistency or variability in processes that lead to inefficiency and poor quality. Uneven workloads, fluctuating production levels, and unpredictable demand are common examples of Mura.

- How to Address Mura:

- Standardize work processes to ensure consistent outputs.

- Level production schedules using techniques like Heijunka.

- Balance workloads across teams to avoid bottlenecks or idle time.

3. Muri: Overburden

Muri refers to the overburdening of people, machines, or systems. Overloading leads to stress, errors, breakdowns, and decreased productivity.

- How to Mitigate Muri:

- Design processes with realistic workloads for employees and equipment.

- Implement automation to handle repetitive or heavy tasks.

- Regularly maintain equipment to ensure optimal performance.

Why Addressing the 3Ms Matters

By systematically eliminating Muda (waste), reducing Mura (unevenness), and avoiding Muri (overburden), organizations can:

- Enhance operational efficiency.

- Improve product or service quality.

- Increase customer satisfaction.

Understanding and applying the 3Ms of Lean Six Sigma creates a foundation for continuous improvement, paving the way for sustainable success in today’s competitive business landscape.

"Streamline your processes, balance your workflows, and empower your team by the 3Ms of Lean Six Sigma!"