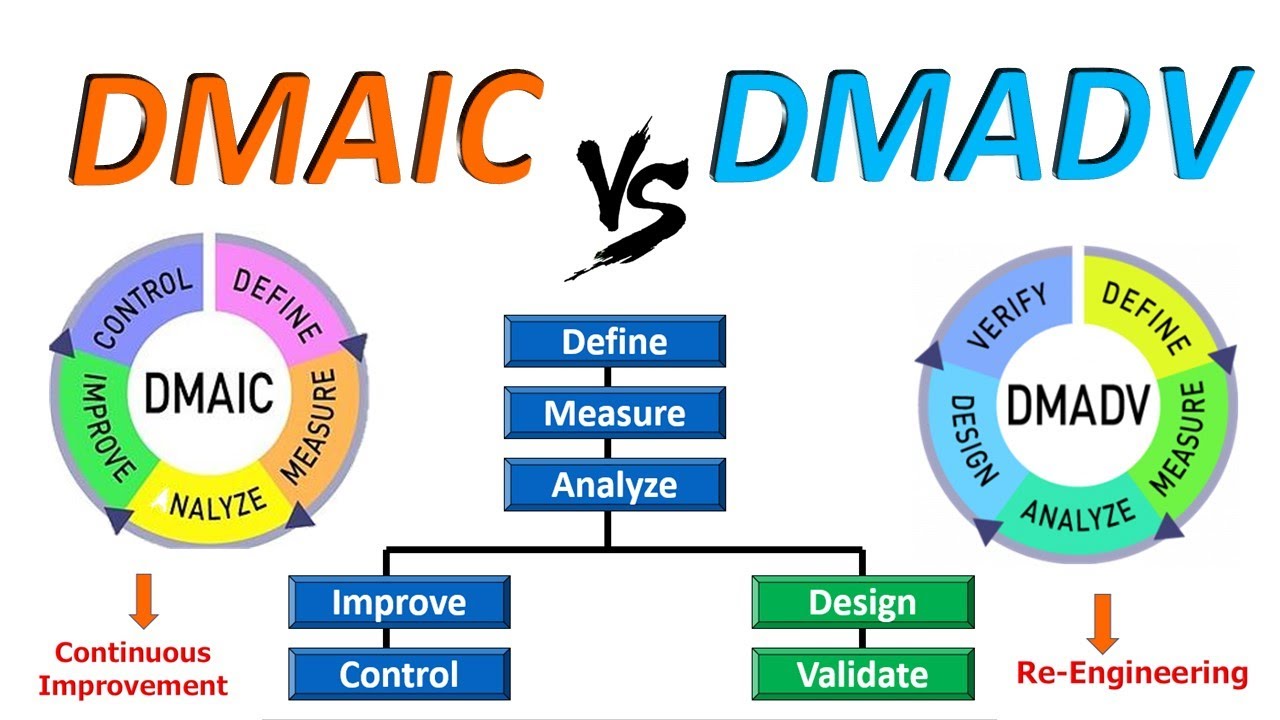

DMAIC vs. DMADV in Six Sigma

DMAIC (Define, Measure, Analyze, Improve, Control) is used to improve existing processes by identifying defects and reducing variation.

DMADV (Define, Measure, Analyze, Design, Verify) is used for designing new processes or products, focusing on meeting customer requirements from the start.

- DMAIC:

- Purpose: Used for improving existing processes.

- Steps:

- Define: Identify the problem.

- Measure: Collect data on current performance.

- Analyze: Identify root causes.

- Improve: Implement solutions.

- Control: Maintain improvements.

- Focus: Correcting deficiencies in existing systems.

-

DMADV:

- Purpose: Used for creating new processes or products.

- Steps:

- Define: Set goals based on customer needs.

- Measure: Define key product or process characteristics.

- Analyze: Develop design alternatives.

- Design: Create the product/process.

- Verify: Test and ensure it meets requirements.

- Focus: Design processes or products from the ground up, ensuring they meet customer requirements from the start.

Both aim for quality but are applied in different scenarios: DMAIC optimizes existing processes, while DMADV focuses on designing new ones.